BRIGHT WASH LIMITED (HAMIM Group)

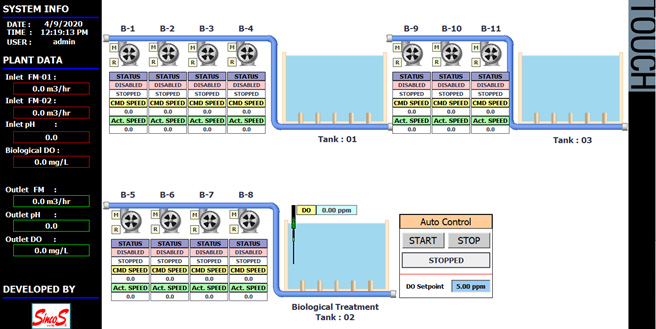

Effluent Treatment Plant (ETP) Automation

Effluent Treatment Plant automation and different parameters monitoring.

Components:

S7 300 PLC, Analog and Digital Inputs and Outputs, TP 700 HMI, SCADA etc.

Process Summary:

The PLC collects reading from Electro Magnetic Flowmeter, Ultrasonic Level Meter, DO Sensor, pH Sensor. The PLC compares the sensor readings with setpoint. When sensor reading is higher than setpoint, the PLC starts the blower pumps sequentially using PID and it turns off the pumps sequentially when DO and pH are close or below the desired level.

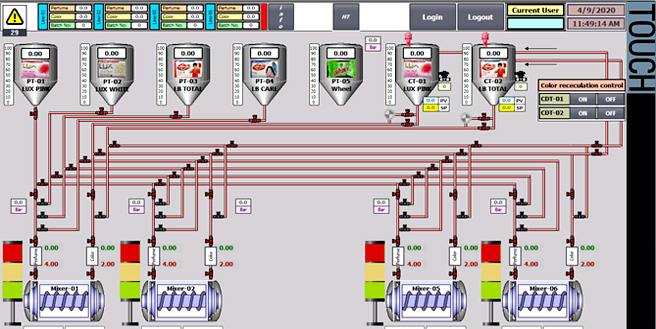

UNILEVER BANGLADESH LTD. (KALURGHAT PLANT)

Color-Perfume Dosing Automation and Data Acquisition

Color and Perfume dosing as per requirement of different types of products to mixing facilities.

Components:

S7 300 PLC, Analog and Digital Inputs and Outputs, SIWAREX Module, HMI TP 1200

Process Summary:

Storage tanks are filled automatically from barrels of color and perfume. Different recipes for different products are saved to the PLC via HMI. The operator selects the required recipe and the dosing pots are filled with required amount of specific color and perfume. When ready, the operator doses the ingredients using HMI. Once empty, the dosing pots and the storage tanks are automatically refilled by PLC. All data are automatically logged in USB drive.

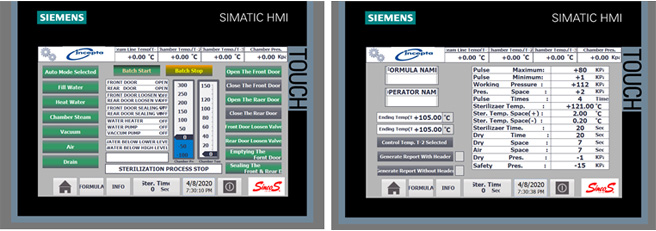

INCEPTA PHARMACEUTICALS LTD.

Autoclave Machine Automation and Data Logging

Sterilization by heating system.

Component:

PLC S-7 1200, Digital and Analog Input and output module, HMI-TP 700 Comfort panel

Process Summary:

Once the sterilization process is started in automatic mode, it checks some pre-requisite conditions like chamber temperature, front and back doors closed condition, chamber pressure and so on. Once the condition is met, in imitation of recipe settings, pre-heating system warm up its chamber after that its heating system makes it heated till its desired temperature reaches. Once the temperature reaches, it controls its temperature to perish bacteria then cleaning system clean its system for next batch. All data logged in USB drive automatically.

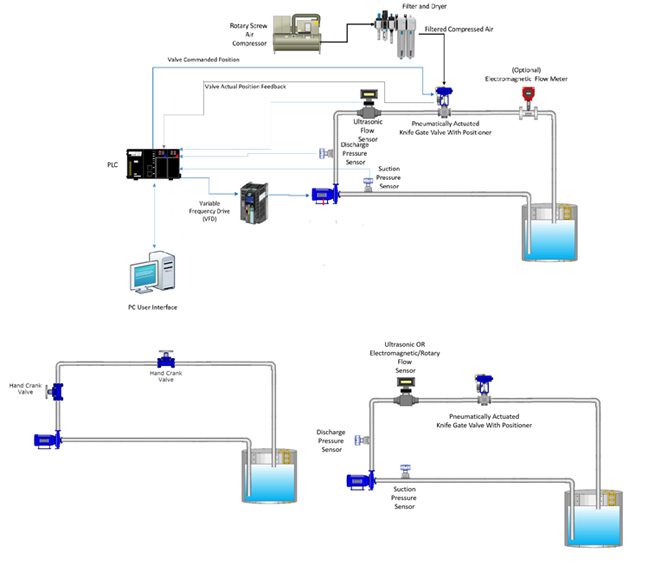

MILITARY INSTITUTE OF SCIENCE AND TECHNOLOGY (MIST)

Hydraulic Pump Testing Bench Automation

Measuring pump efficiency by using water flow from flow meter, pressure from pressure sensor, input power to pump from VFD.

Components:

Process Summary:

Implement turn-key, fully automated centrifugal and submersible pump performance characterization system. Custom built data logging and control software designing. Actuators for accurate control of pipe water flow. Sensors for measurement of water pressure, water flow, VFD for Motor. Efficiency report will be generated after test automatically.

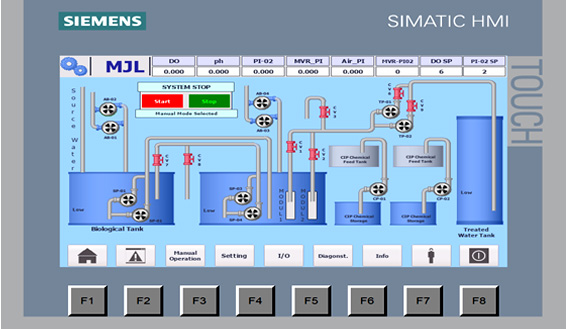

MJL BANGLADESH LIMITED

Black water treatment Plant Automation

Black water treatment, check different water quality parameter and make it ready for reuse.

Component:

PLC CPU S7-1200, Input and output module, KTP 700 etc.

Project summary:

In automatic mode, if everything is in healthy condition and pre-requisite are met, the water treatment process starts. Here, the prerequisites are: water level, treated water demand, water filtration etc.

A suction water pump draws water from the source and store in ‘Biological Tank’, if the water in the ‘Biological Tank’ is below the predefined level. For filtration, this water is transferred from ‘Biological Tank’ to ‘Modulation Tank’. Always, a pair of air blower, situated in each ‘Biological Tank’ and ‘Modulation Tank’, maintain its DO (Dissolved Oxygen) level. Finally, the filtered water is stored in the ‘Treated Water Tank’.

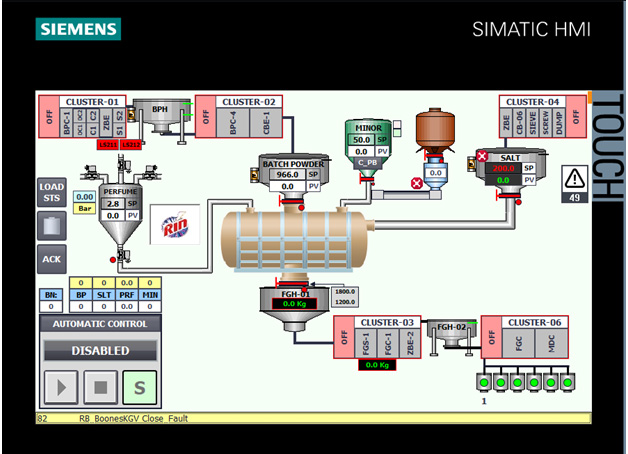

UNILEVER BANGLADESH LTD. (ARC PLANT)

Cascade Boone’s Automation with Data Logging

Loading of Base Powder and salt into the hopper according to the Predefined recipe amount.

Components:

S7 1500 PLC, ET 200MP, Analog and Digital Inputs and Outputs, SIWAREX, TP 900 Comfort Panel etc.

Process:

Base powder from process plant is stored in base powder storage hopper through cluster-01. Loading in base powder dosing hopper depends on batching recipe amount. Salt manually dumps in dumping station and goes to salt dosing hopper through cluster-04. Loading in dosing hopper depends on recipe amount.

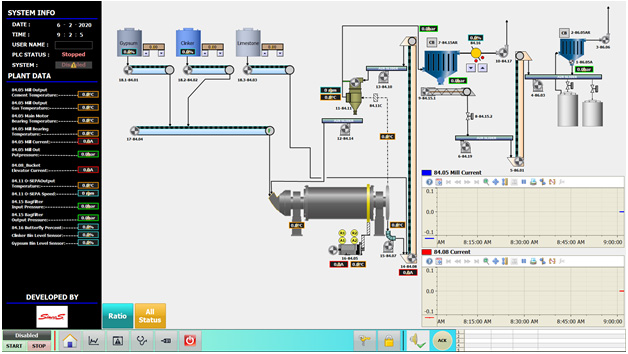

SIAM BANGLA INDUSTRIES LTD

White Cement Process Line Automation & SCADA Development

Sequential operation and real-time monitoring of the production process.

Components:

S7 300 PLC, Analog and Digital Inputs and Outputs, TP 700 HMI, SCADA etc.

Process:

The principle objective of the project is sequential operation of the complete process. The PLC manages the process to ensure maximum production efficiency. Automatic/manual operation and monitoring can be done from SCADA & HMI.

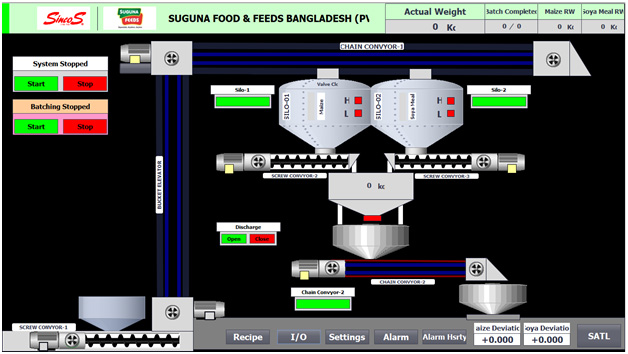

SUGUNA FEED MILLS LTD

Feed Mill Auto Batching Plant Automation

Production of feed mill batch according to defined ingredient weighing recipe menu.

Component:

PLC S7-300, Input and output module, SIWAREX, SCADA etc.

Project summary:

In automatic mode, if everything is in healthy condition like different type of motor, conveyor etc. and pre-requisite like batching demand, Ingredient availability etc. are met, all solid like maize, Soybean and so on are stored in their respective hopper according to batching recipe amount. In imitation of batching recipe, solids are dumped into “Weighing Hopper” and mixed it with mixer. In context of solid, there are only one phase solid to enact a batch and they are dumped and mixed in imitation of process sequence. After making up the process the production goods is dumped into “Base Hopper”.

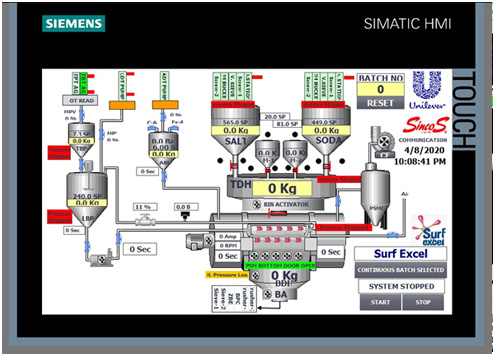

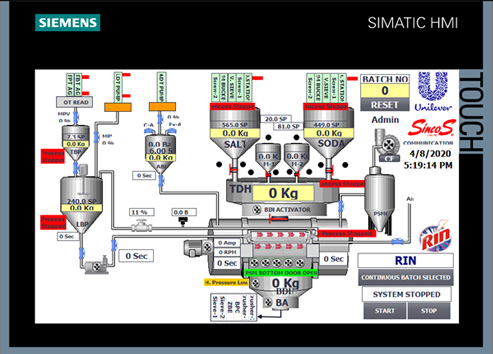

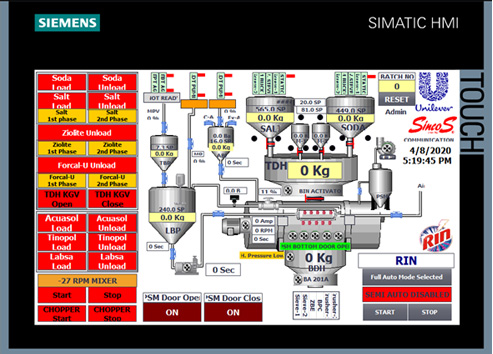

UNILEVER BANGLADESH LIMITED (ARC PLANT)

PSM (Ploughshare Mixer) Process Plant Automation

Production of Surf Excel Base powder according to defined recipe menu.

Components:

S7 300 PLC, IM 153, SIWAREX, HMI-TP900 etc.

Project Summary:

In automatic mode, if everything is in healthy condition like different type of motor, conveyor etc. and pre-requisite like batching demand, Ingredient availability etc. are met, all solid and liquid like salt, Soda, Labsa and so on are stored in their respective hopper according to batching recipe amount. In imitation of batching recipe, solid and liquid are dumped into PSM container and mixed it with different time and mixing speed in different step automatically. In context of Solid and liquid, there are two phase solid and one phase liquid to enact a batch and they are dumped and mixed in imitation of process sequence. After making up the process the production goods is dumped into “Base Powder Hopper”.